HYBRID INFINI DIE’S

“FIRST IMPRESSIONS ARE LASTING IMPRESSIONS”

As a result of acquisitions that were made in 2022, SRD has the rights, expertise and experience to provide the Hybrid Infini-die with its highly regarded reputation within the industry. The Hybrid Infini-die is an advanced die-cutting technology, developed to maximize the manufacturing process for producing value added folding cartons from ‘THE FIRST TO THE LAST IMPRESSION’.

The most significant aspect of the Hybrid Infini-die tool base is that it supports an indefinite number of re-rules and maintains lateral stability. Steel rule components can continuously be removed and inserted, without constant chipping or de-lamination of the die base. The die base incorporates the Infini-Lock Technology which applies and maintains pressure on the steel rule components.

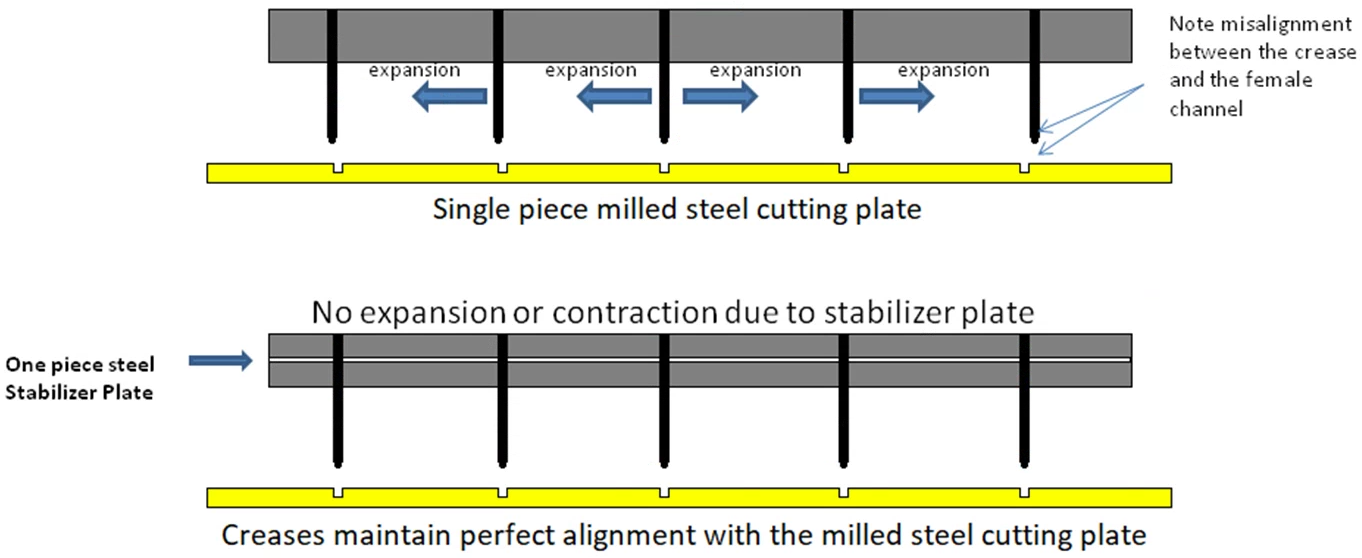

In the illustrations below, the upper view shows a plywood or composite die base which is subject to expansion caused by the accumulative lateral pressure built up when inserting the steel rule components into the laser cut or routed rule slots.

Expansion can also be attributed to moisture entering the porous areas of the die base. Conversely, excessive dryness will cause the die base to contract. It is also understood that the composite die base is a lot less susceptible to expansion and contraction due to moisture, but both will be affected by temperature variations. Therefore we can confidently conclude that the conventional fabrication of lasered or routed die bases using the current plywood or composite die base materials are dimensionally unstable and are therefore rendered unsuitable or unreliable for use with a Milled Steel Cutting Plate.

The insertion of the steel stabilizer core, between the upper and lower die base layers, locks the fixed datum of the steel plate to the outer die base layers preventing their expansion or contraction, thereby ensuring a perfect register of the die with the milled steel cutting plate.

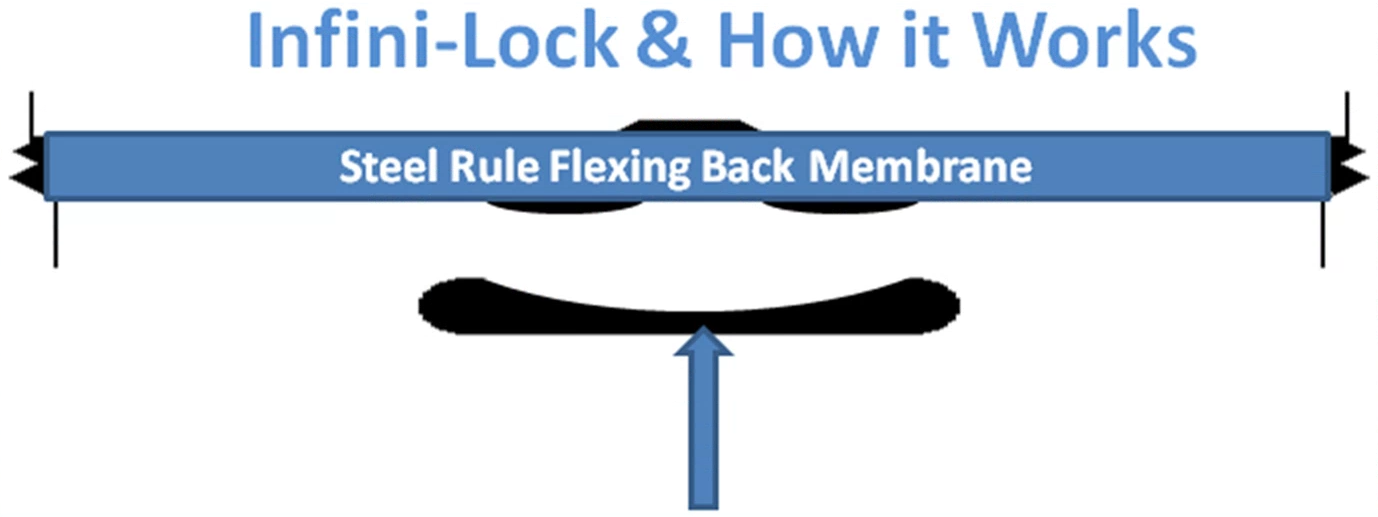

What are Infini-Locks ?

An Infini-Lock is a geometrically designed shape, laser cut into the die base beside any kind of cutting or creasing rule component. This geometric design creates a natural flexible membrane which springs back when the rule is inserted into the die base, thereby exerting and maintaining a consistently controlled amount of pressure against the side of the rule component.

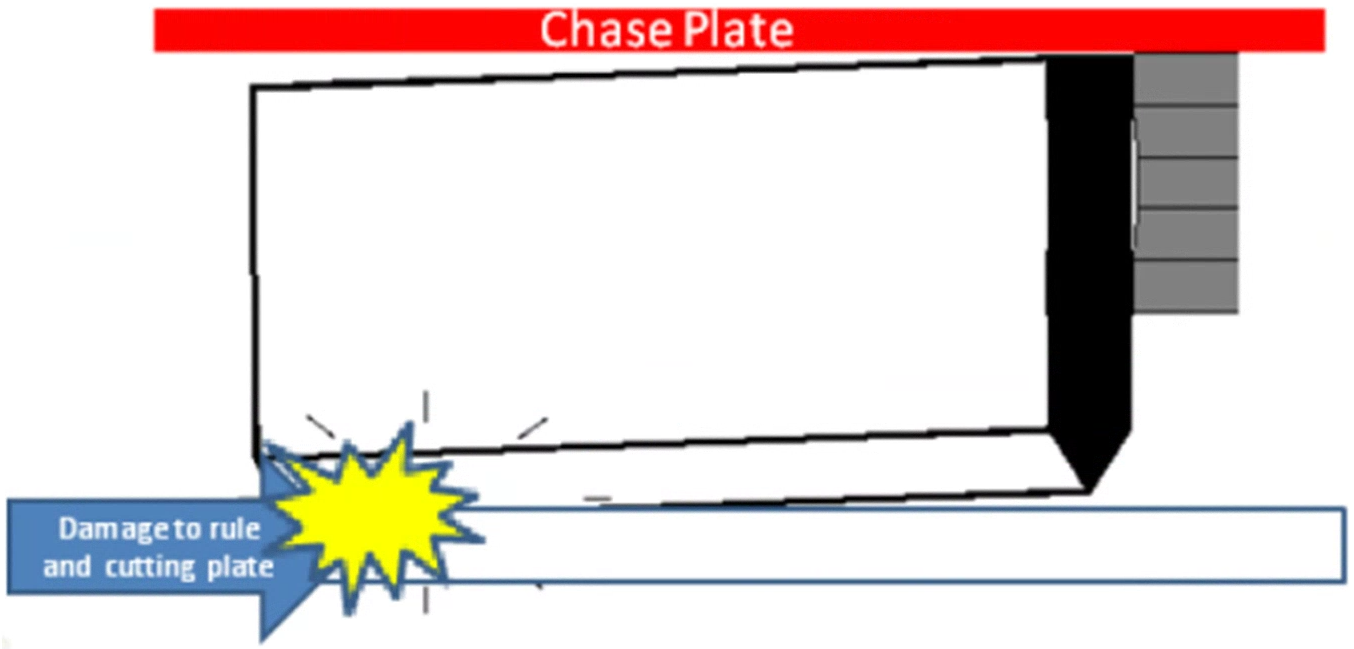

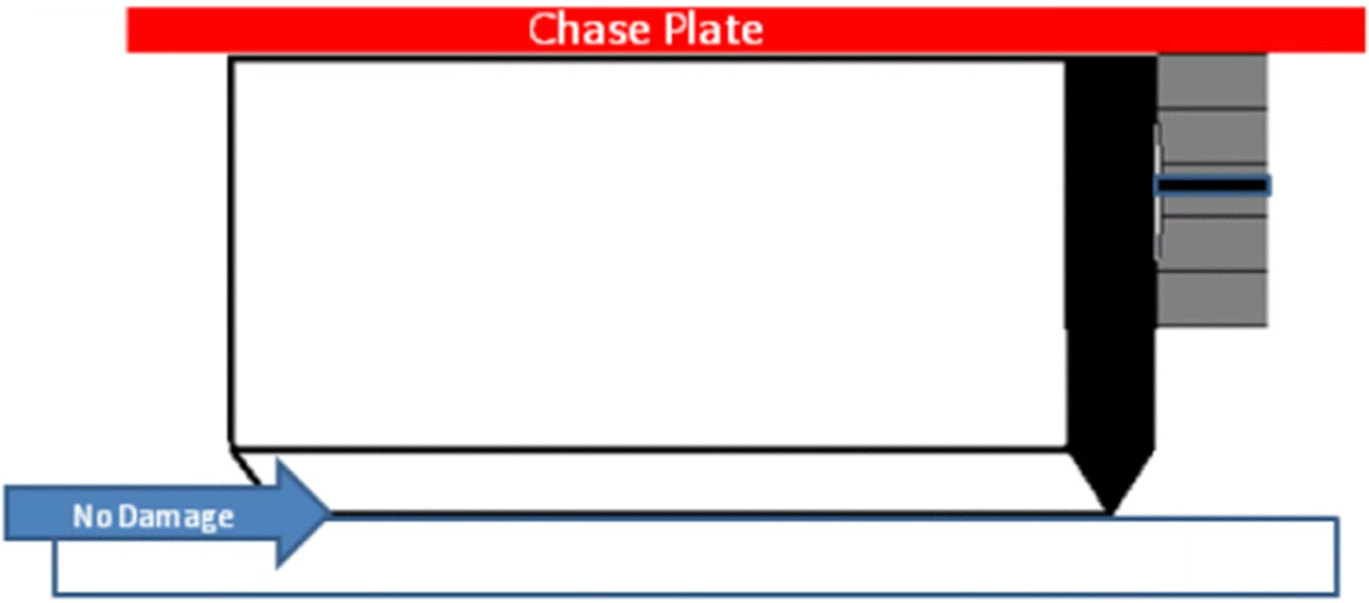

The Infini-Lock lateral flex-locking technology ensures that the rule components throughout the die base are securely retained, yet allowing vertical adjustment of the rules within the die kerf. This unique adjustment feature provides optimal positioning and leveling of the die rules between the cutting and chase backer plates on the first impression, thereby maximizing the die seating, helps to prevent damage to the cutting edges of the rule and reduces make-ready time.

The Infini-Lock lateral flex-locking technology ensures that the rule components throughout the die base are securely retained, yet allowing vertical adjustment of the rules within the die kerf. This unique adjustment feature provides optimal positioning and leveling of the die rules between the cutting and chase backer plates on the first impression, thereby maximizing the die seating, helps to prevent damage to the cutting edges of the rule and reduces make-ready time.

In Summary

By combining both the use of a Steel Stabilizer Plate and the Infini-locks, we are able to significantly reduce or eliminate the amount of expansion or contraction of the die base to ensure that you can effectively utilize our Hybrid Infini-Dies with a Milled Steel Cutting Plate.